Suzuki Sx4 Maintenance Manual 2017

. Indicates special information to make mainte- nance easier or instructions clearer. WARNING: This service manual is intended for authorized SUZUKI dealers and qualified service me- chanics only.

Inexperienced mechanics or mechanics without the proper tools and equipment may not be able to properly per- form the services described in this manual. Therefore, note that illustra- tions may differ from the vehicle being actually serviced.

Get Suzuki SX4 repair and maintenance costs, common problems, recalls, and more. Find certified Suzuki mechanics near you. View and Download Suzuki Swift user manual online. Swift Suzuki. Suzuki sx4 crossover owner's manual. MAINTENANCE AND LUBRICATION 0B-3 This table includes. Owner's Manuals. Important System Requirements for '24 Hour Online View' of owner's Information. All online viewing of Suzuki service literature and manuals require a Windows based PC, or Laptop with Internet Explorer 10 or 11 to correctly view the information.

The right is reserved to make changes at any time without notice. OVERSEAS SERVICE DEPARTMENT COPYRIGHT SUZUKI MOTOR CORPORATION 2000. RELATED MANUALS Related manuals listed below are in the chronological order with the latest one at the top. For the efficient use of manuals, start with one at the top of the list (i.e., the latest one). If desired section, item or description is not found in it, try next one in the list and do the same one by one till what is being searched is found. TABLE OF CONTENTS SECTION GENERAL INFORMATION General Information Maintenance and Lubrication HEATING AND AIR CONDITIONING Heater and Ventilation Air Conditioning (Oprional) ENGINE General Information and Diagnosis (TBI for G10) General Information and Diagnosis (TBI for G13) General lnformation and Diagnosis (SFI for G13) Engine Mechanical (G10 Engine) Engine Mechanical. GENERAL INFORMATION 0A-1 SECTION 0A GENERAL INFORMATION CONTENTS HOW TO USE THIS MANUAL.

0A- 2 PRECAUTIONS. 0A-2 GENERAL INFORMATION HOW TO USE THIS MANUAL 1) There is a TABLE OF CONTENTS FOR THE WHOLE MANUAL on the third page of this manual, whereby you can easily find the section that offers the information you need.

Also, there is a CONTENTS on the first page of EACH SECTION, where the main items in that section are listed. D If the air bag system and another vehicle system both need repair, Suzuki recommends that the air bag system be repaired first, to help avoid unintended air bag deploy- ment. 0A-4 GENERAL INFORMATION HANDLING AND SERVICING ALWAYS CARRY AIR BAG (INFLATOR) MODULE WITH TRIM COVER (AIR BAG OPENING) AWAY WARNING: FROM BODY. D Many of service procedures require disconnection of “AIR BAG” fuse and air bag (inflator) modules (driver and passenger) from deployment loop to avoid an accidental deployment. GENERAL INFORMATION 0A-5 CAUTION: D Even when the accident was light enough not to cause air bags to deploy, be sure to inspect system parts and other related parts according to instructions under “Repair and Inspection Required after an Accident” in Section 9J. D When servicing parts other than air bag system, if shocks may be applied to air bag system component parts, re- move those parts beforehand.

0A-6 GENERAL INFORMATION GENERAL PRECAUTIONS The WARNING and CAUTION below describe some general precautions that you should observe when servicing a vehicle. These general precautions apply to many of the service procedures described in this manual, and they will not necessarily be repeated with each procedure to which they apply. WARNING: D Whenever raising a vehicle for service, be sure to follow the instructions under “VEHICLE LIFTING POINTS”. GENERAL INFORMATION 0A-7 D When removing the battery, be sure to disconnect the nega- tive cable first and then the positive cable. When reconnect- ing the battery, connect the positive cable first and then the negative cable, and replace the terminal cover.

D When removing parts that are to be reused, be sure to keep them arranged in an orderly manner so that they may be rein- stalled in the proper order and position. 0A-8 GENERAL INFORMATION D When disconnecting vacuum hoses, attach a tag describing the correct installation positions so that the hoses can be re- installed correctly. D After servicing fuel, oil, coolant, vacuum, exhaust or brake systems, check all lines related to the system for leaks. D For vehicles equipped with fuel injection systems, never dis- connect the fuel line between the fuel pump and injector without first releasing the fuel pressure, or fuel can be. GENERAL INFORMATION 0A-9 D Always be careful not to handle electrical parts (computer, relay, etc.) in a rough manner or drop them. PRECAUTIONS FOR CATALYTIC CONVERTER For vehicles equipped with a catalytic converter, use only un- leaded gasoline and be careful not to let a large amount of un- burned gasoline enter the converter or it can be damaged.

0A-10 GENERAL INFORMATION D When disconnecting connectors, never pull the wiring har- ness. Unlock the connector lock first and then pull them apart by holding connectors themselves. D When connecting connectors, also hold connectors and put them together until they lock securely (a click is heard). D When installing the wiring harness, fix it with clamps so that no slack is left. GENERAL INFORMATION 0A-11 D Be careful not to touch the electrical terminals of parts which use microcomputers (e.g. Electronic control unit like as ECM, PCM, P/S controller, etc.). The static electricity from your body can damage these parts.

D Never connect any tester (voltmeter, ohmmeter, or whatever) to electronic control unit when its coupler is disconnected. 0A-12 GENERAL INFORMATION D When checking connection of terminals, check its male half for bend and female half for excessive opening and both for locking (looseness), corrosion, dust, etc. D Before measuring voltage to check for electrical system, check to make sure that battery voltage is 11 V or higher.

Such terminal voltage check at low battery voltage will lead to erroneous diagnosis. GENERAL INFORMATION 0A-13 3) Using a test male terminal, check both terminals of the circuit be- ing checked for contact tension of its female terminal. Check each terminal visually for poor contact (possibly caused Check contact tension by inserting and removing just by dirt, corrosion, rust, entry of foreign object, etc.). 0A-14 GENERAL INFORMATION If measurements were taken as shown in the figure at the left and results were as listed below, it means that the circuit is open be- tween terminals B-1 and A-1. Voltage Between: C-1 and body ground: Approx. 5 V B-1 and body ground: Approx. GENERAL INFORMATION 0A-15 INTERMITTENT AND POOR CONNECTION Most intermittent are caused by faulty electrical connections or wir- ing, although a sticking relay or solenoid can occasionally be at fault.

When checking it for proper connection, perform careful check of suspect circuits for: D Poor mating of connector halves, or terminals not fully seated in the connector body (backed out). 0A-16 GENERAL INFORMATION PRECAUTION FOR INSTALLING MOBILE COMMUNICATION EQUIPMENT When installing mobile communication equipment such as CB (Citi- zens-Band)-radio or cellular-telephone, be sure to observe the fol- lowing precautions. Failure to follow cautions may adversely affect electronic control system. D Keep the antenna as far away as possible from the vehicle’s elec- tronic control unit. GENERAL INFORMATION 0A-17 PRECAUTION IN SERVICING FULL-TIME 4WD VEHICLE When performing any of the following types of work, be sure to make the vehicle as front wheel drive by cutting transmission of driving force to the rear wheels. Otherwise, rear wheels are driven and vehicle accidents, damage and personal injury may result. 0A-18 GENERAL INFORMATION IDENTIFICATION INFORMATION VEHICLE IDENTIFICATION NUMBER The number is punched on the front dash panel in the engine room.

IDENTIFICATION WHETHER VEHICLE EQUIPPED WITH WU-TWC OR NOT It can be identified by the shape of exhaust manifold (1) and ex- haust pipe (2). GENERAL INFORMATION 0A-19 WARNING, CAUTION AND INFORMATION LABELS The figure below shows main labels among others that are attached to vehicle component parts. When servicing and handling parts, refer to WARNING/CAUTION instructions printed on labels. If any WARNING/CAUTION label is found stained or damaged, clean or replace it as necessary. NOTE: Air bag CAUTION / WARNING labels are attached on the vehicle equipped with air bag system only. 0A-20 GENERAL INFORMATION VEHICLE LIFTING POINTS WARNING: D Before applying hoist to underbody, always take vehicle balance throughout service into consider- ation.

Vehicle balance on hoist may change depending of what part to be removed. D Before lifting up the vehicle, check to be sure that end of hoist arm is not in contact with brake pipe, fuel pipe, bracket or any other part. GENERAL INFORMATION 0A-21 In raising front or rear vehicle end off the floor by jacking, be sure When using floor jack: to put the jack against the center portion of front cross member (1) or rear cross member (2). WARNING: D Never apply jack against suspension parts (i.e., stabilizer, etc.) or vehicle floor, or it may get deformed.

0A-22 GENERAL INFORMATION ABBREVIATIONS AND SYMBOLS MAY BE USED IN THIS MANUAL ABBREVIATIONS: Anti-Lock Brake System EBCM: Electronic Brake Control ATDC: After Top Dead Center Module, ABS Control Module: American Petroleum Institute: Engine Control Module: Automatic Transmission Fluid ECT Sensor: Engine Coolant Temperature. GENERAL INFORMATION 0A-23: Left Hand: Throttle Body Fuel Injection LSPV: Load Sensing Proportioning (Single-Point Fuel Injection, Valve SPI): Torque Converter Clutch: Transmission Control Module MAF Sensor: Mass Air Flow Sensor (Air Flow (A/T Controller, A/T Control Sensor, AFS, Air Flow Meter, Module) AFM). 0A-24 GENERAL INFORMATION SYMBOLS SYMBOL DEFINITION SYMBOL DEFINITION Tightening torque Apply SUZUKI BOND NO. 1216 0 Apply oil (Engine, transmission, Apply SILICONE SEALANT transfer, differential) 0 Apply fluid (Brake, power steering or Apply SEALING COMPOUND 366E automatic transmission fluid) 0. GENERAL INFORMATION 0A-25 FASTENERS INFORMATION METRIC FASTENERS Most of the fasteners used for this vehicle are metric fasteners. When replacing any fasteners, it is most important that replacement fasteners be the correct diameter, thread pitch and strength.

FASTENER STRENGTH IDENTIFICATION Most commonly used metric fastener strength property classes are 4T, 6.8, 7T, 8.8 and radial line with the class identification embossed on the head of each bolt. 0A-26 GENERAL INFORMATION STANDARD TIGHTENING TORQUE Each fastener should be tightened to the torque specified in each section of this manual. If no description or specifi- cation is provided, refer to the following tightening torque chart for the applicable torque for each fastener.

When a fastener of greater strength than the original one is used, however, use the torque specified for the original fasten- NOTE: D For the flanged bolt, flanged nut and self-lock nut of 4T and 7T strength, add 10% to the tightening torque. D Service on and around the air bag system components or wiring must be performed only by an autho- rized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under “Gener- al Description” in air bag system section in order to confirm whether you are performing service on or near the air bag system components or wiring.

0B-2 MAINTENANCE AND LUBRICATION MAINTENANCE SCHEDULE NORMAL CONDITION SCHEDULE This table includes services as scheduled up to 90,000 km (54,000 miles) mileage. Beyond 90,000 km (54,000 miles), carry out the same services at Interval: the same intervals respectively. This interval should be judged by 1,000) odometer reading or months, whichever comes first. MAINTENANCE AND LUBRICATION 0B-3 This table includes services as scheduled up to 90,000 km (54,000 miles) mileage. Beyond 90,000 km (54,000 miles), carry out the same services at Interval: the same intervals respectively.

This interval should be judged by This interval should be judged by 1,000) odometer reading or months, whichever comes first. 0B-4 MAINTENANCE AND LUBRICATION MAINTENANCE RECOMMENDED UNDER SEVERE DRIVING CONDITIONS If the vehicle is usually used under the conditions corresponding to any severe condition code given below, it is recommended that applicable maintenance operation be performed at the particular interval as given in the chart below. MAINTENANCE AND LUBRICATION 0B-5 MAINTENANCE SERVICE ENGINE ITEM 1-1 Drive Belt Inspection and Replacement WARNING: Disconnect negative cable at battery before checking and replacing belt. A/C Compressor and/or Power Steering Pump Drive Belt Vehicle with A/C Inspection (If equipped) 1) Detach air cleaner assembly from vehicle body and shift its posi- tion.

0B-6 MAINTENANCE AND LUBRICATION Water Pump Belt Replacement Replace belt with a new one. Refer to SECTION 6B for replacement procedure of pump belt.

NOTE: When replacing belt with a new one, adjust belt tension to 5 – 7 mm (0.20 – 0.27 in.). ITEM 1-2 Camshaft Timing Belt Replacement Replace belt with new one. MAINTENANCE AND LUBRICATION 0B-7 ITEM 1-4 Proper Engine Oil Viscosity Chart Engine Oil and Filter Change WARNING: New and used engine oil can be hazardous. Be sure to read “WARNING” in General Precaution in SEC- TION 0A and observe what in written there. Use engine oil of SE, SF, SG, SH or SJ grade.

Miller solutions. Advanced Assembly Language Programming.

0B-8 MAINTENANCE AND LUBRICATION 7) Replenish oil until oil level is brought to FULL level mark on dip- stick (oil pan and oil filter capacity). Filler inlet is at the top of cyl- inder head cover. 8) Start engine and run it for three minutes. Stop it and wait another 5 minutes before checking oil level.

MAINTENANCE AND LUBRICATION 0B-9 1) Remove radiator cap when engine is cool. 2) Loosen radiator drain plug (1) to drain coolant. 3) Remove reservoir and drain. 4) Tighten drain plug securely. Also install reservoir. 5) Slowly pour specified amount of coolant to the base of radiator filler neck, and run engine, with radiator cap removed, until ra- diator upper hose is hot.

0B-10 MAINTENANCE AND LUBRICATION IGNITION SYSTEM ITEM 2-1 Spark Plugs Replacement Replace spark plugs with new ones referring to SECTION 6F or 6F1. ITEM 2-2 Distributor Cap and Rotor Inspection (if equipped) D Check distributor cap and rubber caps for cracks.

D Clean dusty and stained parts using a dry, soft cloth. MAINTENANCE AND LUBRICATION 0B-11 2) Visually check that air cleaner filter is not excessively dirty, dam- 1.0 liter engine aged or oily. 3) Clean filter with compressed air from air outlet side of filter. 4) Install air cleaner filter into case. 5) Clamp case cap securely and install hose to case and bracket if removed. 0B-12 MAINTENANCE AND LUBRICATION EMISSION CONTROL SYSTEM ITEM 4-1 PCV (Positive Crankcase Ventilation) Valve Inspection Check crankcase ventilation hoses and PCV hoses for leaks, cracks or clog, and PCV valve (1) for stick or clog. Refer to ON-VE- HICLE SERVICE of SECTION 6E1 or 6E2 for PCV valve checking procedure.

MAINTENANCE AND LUBRICATION 0B-13 ITEM 5-2 Brake Hoses and Pipes Inspection Perform this inspection where there is enough light and use a mirror as necessary. D Check brake hoses and pipes for proper hook-up, leaks, cracks, chafing, wear, corrosion, bends, twists and other damage.

Replace any of these parts as necessary. 0B-14 MAINTENANCE AND LUBRICATION ITEM 5-4 “a”: Parking brake lever stroke: Brake Lever and Cable Inspection 4 – 9 notches (With 20 kg or 44 lbs of pull pressure) Parking brake lever D Check tooth tip of each notch for damage or wear. If any damage or wear is found, replace parking lever. MAINTENANCE AND LUBRICATION 0B-15 Wheel disc inspection Inspect each wheel disc for dents, distortion and cracks. A disc in badly damaged condition must be replaced. Tire rotation Rotate tires referring to SECTION 3F.

Wheel Bearing Inspection 1) Check front wheel bearing for wear, damage, abnormal noise or rattles. 0B-16 MAINTENANCE AND LUBRICATION D Check front and rear suspension systems for damaged, loose or missing parts; also for parts showing signs of wear or lack of lu- brication. Repair or replace defective parts, if any. D Check front suspension arm ball joint stud dust seals for leakage, detachment, tear or any other damage. MAINTENANCE AND LUBRICATION 0B-17 ITEM 6-7 Manual Transmission Oil Inspection and Change Inspection 1) Inspect transmission case for evidence of oil leakage.

Repair leaky point if any. 2) Make sure that vehicle is placed level for oil level check. 3) Remove oil level plug of transmission. 4) Check oil level. 0B-18 MAINTENANCE AND LUBRICATION ITEM 6-9 Automatic Transmission Fluid level inspection 1) Inspect transmission case for evidence of fluid leakage.

Repair leaky point, if any. 2) Make sure that vehicle is placed level for fluid level check.

3) Check fluid level. For fluid level checking procedure, refer to ON-VEHICLE SER- VICE in SECTION 7B and be sure to perform it under specified conditions. MAINTENANCE AND LUBRICATION 0B-19 ITEM 6-10 All Latches, Hinges and Locks Inspection Doors Check that each door of front, rear and back doors opens and closes smoothly and locks securely when closed.

If any malfunction is found, lubricate hinge and latch or repair door lock system. 0B-20 MAINTENANCE AND LUBRICATION FINAL INSPECTION Exhaust System Check Check for leakage, cracks or loose supports. WARNING: Clutch (For manual transmission) When carrying out road tests, select a safe Check for the following. Place where no man or no running vehicle is D Clutch is completely released when depressing seen so as to prevent any accident. MAINTENANCE AND LUBRICATION 0B-21 Parking brake Body, Wheels and Power Transmitting System Check that lever has proper travel. Check that body, wheels and power transmitting sys- tem are free from abnormal noise and abnormal WARNING: vibration or any other abnormal condition.

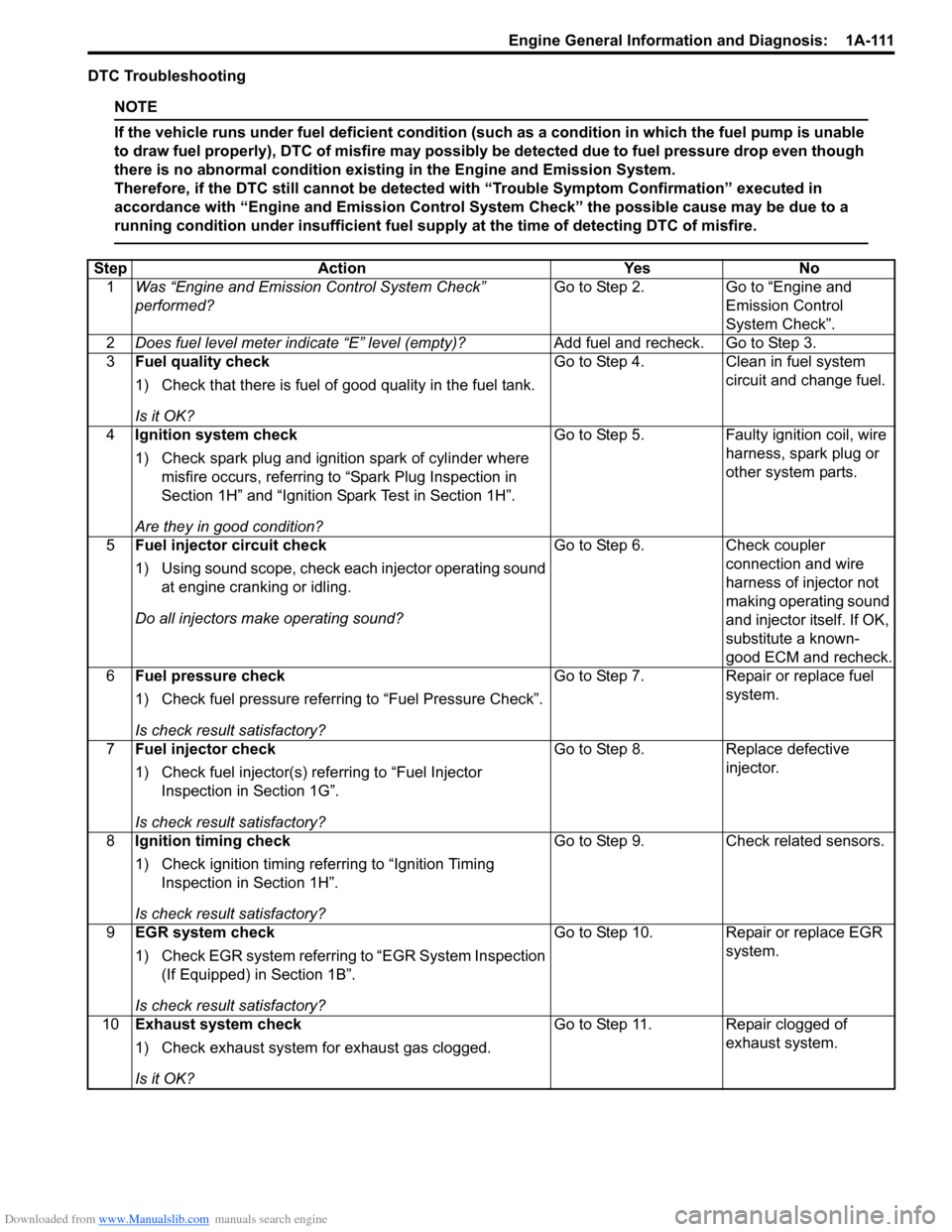

With vehicle parked on a fairly steep slope, Meters and Gauge make sure nothing is in the way downhill to. D Service on and around the air bag system components or wiring must be performed only by an autho- rized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under “Gener- al Description” in air bag system section in order to confirm whether you are performing service on or near the air bag system components or wiring. 6-2 ENGINE GENERAL INFORMATION AND DIAGNOSIS (TBI FOR G10) Diagnostic Trouble Code Clearance.6-14 DTC P0302 Cylinder 2 Misfire Detected 6- 68 Diagnostic Trouble Code Table.6-15 DTC P0303 Cylinder 3 Misfire Detected 6- 68. ENGINE GENERAL INFORMATION AND DIAGNOSIS (TBI FOR G10) 6-3 GENERAL INFORMATION STATEMENT ON CLEANLINESS AND CARE An automobile engine is a combination of many machined, honed, polished and lapped surfaces with tolerances that are measured in the thousands of an millimeter (ten thousands of an inch). Accordingly, when any internal engine parts are serviced, care and cleanliness are important. 6-4 ENGINE GENERAL INFORMATION AND DIAGNOSIS (TBI FOR G10) PRECAUTION ON FUEL SYSTEM SERVICE HOSE CONNECTION D Work must be done with no smoking, in a well-ventilated area and With short pipe, fit hose as far as it reaches pipe joint as away from any open flames.

ENGINE GENERAL INFORMATION AND DIAGNOSIS (TBI FOR G10) 6-5 FUEL PRESSURE RELIEF PROCEDURE CAUTION: This work must not be done when engine is hot. If done so, it may cause adverse effect to catalyst. After making sure that engine is cold, release fuel pressure as fol- lows. ECM (PCM) memory as freeze frame data. (For the details, refer to description on Freeze frame data.) D It is possible to communicate by using not only SUZUKI scan tool (Tech-1) (2) but also generic scan tool.

(Diagnostic information. ENGINE GENERAL INFORMATION AND DIAGNOSIS (TBI FOR G10) 6-7 Warm-up Cycle A warm-up cycle means sufficient vehicle operation such that the coolant temperature has risen by at least 22C (40F) from engine starting and reaches a minimum temperature of 70C (160F). Driving Cycle A “Driving Cycle”. DLC (1) is in compliance with SAEJ1962 in its installation position, line the shape of connector and pin assignment. Serial data line (K line of ISO 9141) is used for SUZUKI scan tool (Tech-1) or generic scan tool to communicate with ECM (PCM). ECM (PCM) memory. D Diagnostic information stored in ECM (PCM) memory can be cleared as well as checked by using SUZUKI scan tool (Tech-1) or generic scan tool.

Suzuki Sx4 Maintenance Manual

Before using scan tool, read its Operator’s (Instruction) Manual carefully to have good understanding as to what functions are available and how to use it. 6-10 ENGINE GENERAL INFORMATION AND DIAGNOSIS (TBI FOR G10) ENGINE DIAGNOSTIC FLOW TABLE Refer to the following pages for the details of each step. STEP ACTION Customer Complaint Analysis Go to Step 2. Perform customer 1) Perform customer complaint analysis referring to the complaint analysis. ENGINE GENERAL INFORMATION AND DIAGNOSIS (TBI FOR G10) 6-11 1.

Car Maintenance Manual

CUSTOMER COMPLAINT ANALYSIS Record details of the problem (failure, complaint) and how it occurred as described by the customer. For this purpose, use of such an inspection form will facilitate collecting information to the point required for proper analysis and diagnosis.

6-12 ENGINE GENERAL INFORMATION AND DIAGNOSIS (TBI FOR G10) CUSTOMER PROBLEM INSPECTION FORM (EXAMPLE) User name: Model: VIN: Date of issue: Date Reg. Date of problem: Mileage: PROBLEM SYMPTOMS j Difficult Starting j Poor Driveability j No cranking j Hesitation on acceleration j No initial combustion j Back fire/jAfter fire j No combustion. “Diagnostic Flow Table A-2” for troubleshooting. DIAGNOSTIC TROUBLE CODE (DTC) CHECK 1) Prepare SUZUKI scan tool (Tech-1) or generic scan tool. 2) With ignition switch OFF, connect it to data link connector (DLC) (1) located on underside of instrument panel at driver’s seat side. 6-14 ENGINE GENERAL INFORMATION AND DIAGNOSIS (TBI FOR G10) DIAGNOSTIC TROUBLE CODE (DTC) CLEARANCE 1) Connect SUZUKI scan tool (Tech-1) or generic scan tool to data link connector in the same manner as when making this connec- tion for DTC check.